- June 03, 2014

- By Karen Shih ’09

Want to create a custom cookie cutter? Make personalized figurines for your kids? Replace a shower hook on the fly? Two Terps have developed a mini 3-D printer that allows you to do all that and more from your desk at home.

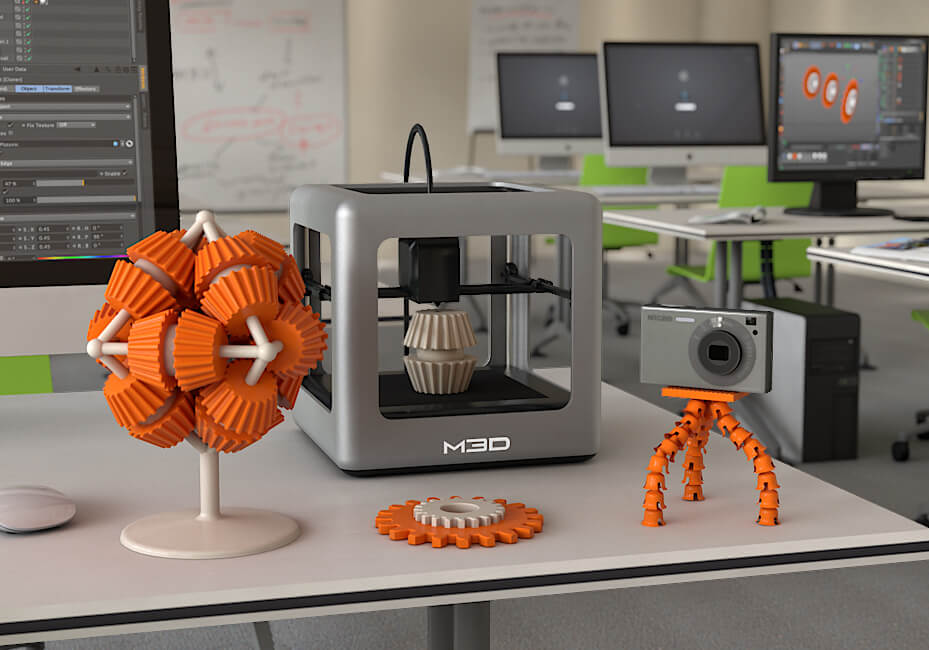

“The Micro,” the new printer from M3D, founded by Michael Armani ’05, Ph.D. ’10 and David Jones ’06, is inexpensive, sleek and made for the masses.

Inspired by how toy helicopters went from hobby toys that cost thousands to mass-market products that could be sold at the mall, they decided to do the same for 3-D printers.

In April, after two years of development, they launched a Kickstarter campaign, hoping to raise $50,000.

“We had humble expectations,” Armani says. “We self-funded this thing and had started borrowing, and all we needed was that last push.”

They hit their goal in just 11 minutes—and after a month, raised more than $3.4 million from nearly 12,000 backers.

Watch their Kickstarter video to see the Micro in action.

It was exhilarating, of course, and it validated their belief that there was a demand for this type of product. But with more backers also came more orders, and the guys are ramping up production to deliver their first printers to the highest backers this fall. The rest of the backers and consumers who pre-order on the M3D site will get their printers in early 2015. They’re priced at $349, compared to thousands of dollars for larger, more complicated 3-D printers.

M3D claims 15 innovations that set the Micro apart, including low power consumption, quietness, automatic leveling and calibration (which otherwise must be done by hand), as well as a commitment to U.S. manufacturing. The company even created its own color-changing filaments (the material used to print objects), though the printer is compatible with standard filaments available on the market.

The Micro can be used with any Windows, Max or Linux-based system, and the software is designed to be “as interactive and enjoyable as a game,” according to the M3D site.

Armani, an engineer, and Jones, a computer scientist, agonized over every aspect of the design. “Mike and I would always come at it from different angles,” says Jones. “We’d have very productive, sometimes very heated debates, and that’s what’s made the Micro so great. It’s not just a beautiful design that doesn’t work well, it isn’t just an ugly design that works really well—it’s a meshing of two completely different points of view.”

Their partnership goes back more than a decade, to when the met in a biology class at UMD and “didn’t stop talking the whole day,” Armani says.

They credit their outside-the-classroom experiences at Maryland, including lots of undergraduate research and even an autonomous robot race, with giving them the background and drive to create their own product.

“I often found myself so absorbed in working on side projects with Mike and other students, I didn’t do so well in my classes,” Jones said. “But we had a fantastic time trying to predict the stock market and all kinds of other projects, and that’s where it all started.”

M3D, based in Bethesda, Md., has a team of about 15 employees, but Armani and Jones hope to expand to up to 200 in the next year. They look to UMD as a major source of talent: Many of their employees are Maryland grads, and they have a dozen or so interns from UMD as well.

“We know there are some really smart people at UMD just waiting to make their mark on the world,” Jones says.