- April 17, 2019

- By Eric Bender

While turning salty water potable can help fill a dangerous gap for the billion or so people who lack access to safe drinking water, traditional desalination systems are often unaffordable in low-income countries and remote areas where they’re needed most.

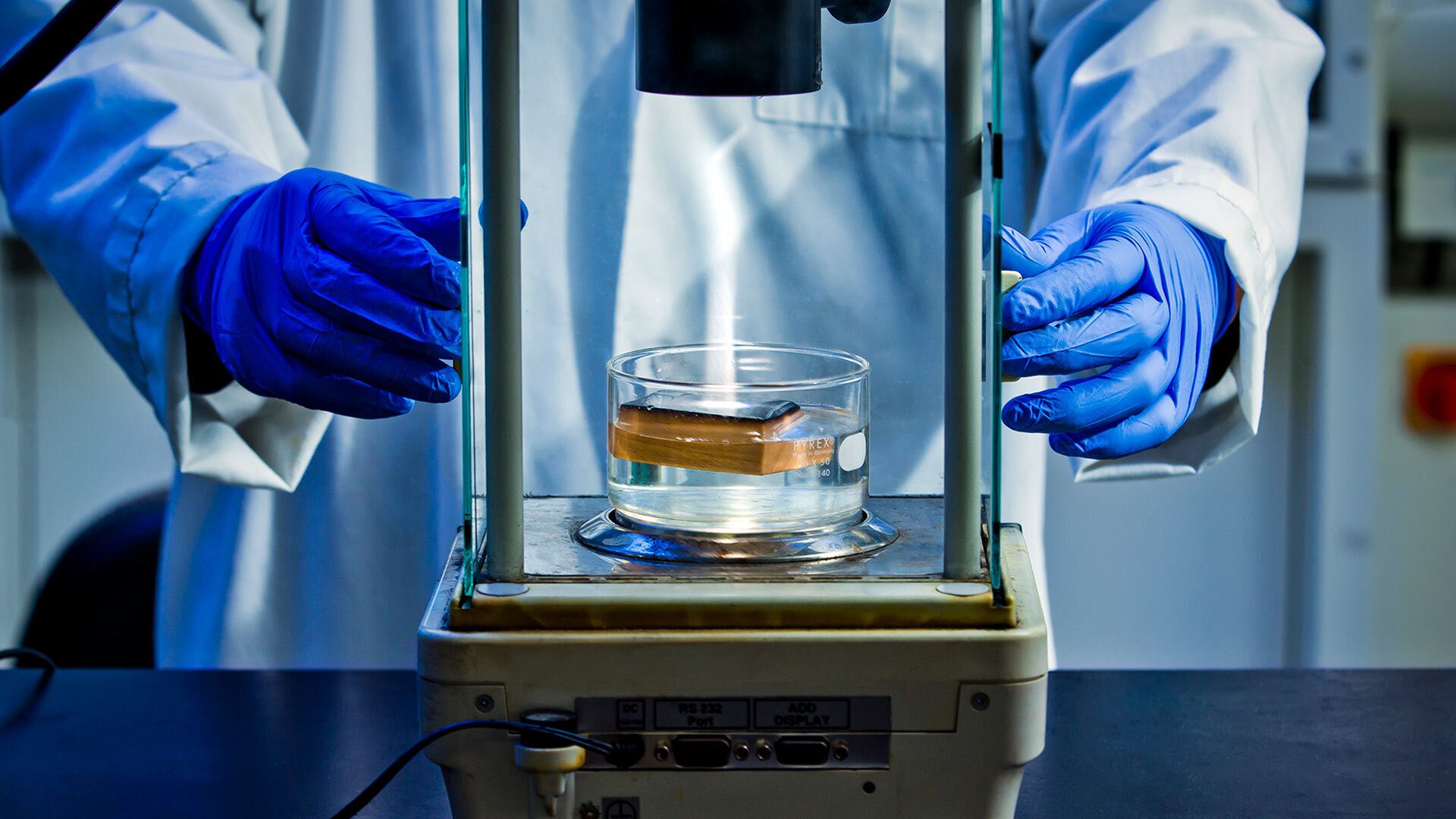

Now, researchers at the A. James Clark School of Engineering have demonstrated a successful prototype of one critical component for affordable small-scale desalination: an inexpensive solar evaporator made of wood, described in a research paper published yesterday in Advanced Materials

The evaporator generates steam with high efficiency and minimal need for maintenance, says Liangbing Hu, associate professor of materials science and engineering, affiliate of the Maryland Energy Innovation Institute and the paper’s senior author.

The design employs a technique known as interfacial evaporation, “which shows great potential in response to global water scarcity because of its high solar-to-vapor efficiency, low environmental impact, and portable device design with low cost,” Hu says. “These features make it suitable for off-grid water generation and purification, especially for low-income countries.”

Interfacial evaporators are made of thin materials that float on saline water and absorb solar heat, producing steam that’s captured and condensed into fresh water. The salt, meanwhile, remains on the evaporators and is occasionally removed to maintain performance.

Hu and his colleagues minimized the need for this maintenance with a device made out of basswood that exploits the wood’s natural structure of the micron-wide channels that carry water and nutrients up the tree.

The researchers supplement these natural channels by drilling a second array of millimeter-wide channels through a thin cross-section of the wood, says Yudi Kuang, a visiting scholar and lead author on the paper. The investigators then briefly expose the top surface to high heat, which carbonizes the surface for greater solar absorption.

In operation, as the device absorbs solar energy, it draws up salty water through the wood’s natural micron-wide channels. Salt is spontaneously exchanged from these tiny channels through natural openings along their sides to the vastly wider drilled channels, and then easily dissolves back into the water below.

“In the lab, we have successfully demonstrated excellent anti-fouling in a wide range of salt concentrations, with stable steam generation with about 75% efficiency,” says Kuang.

Among other projects, Hu’s lab has created light and effective “nanowood” insulating materials and engineered “super wood” that’s 12 times stronger and 10 times tougher than natural wood—a potentially replacement for steel, titanium or carbon fiber in certain applications.

“Wood is an intriguing material scaffold, with its unique hierarchically porous structure, and it is a renewable, abundant and cost-effective resource,” Hu says. “In our lab, the fundamental understanding of biomaterials—especially wood—leads us to achieve extraordinary performance that is competitive with widely used but non-sustainable materials.”