- May 23, 2019

- By Martha Heil

The same tiny structures in wood that carry water and nutrients to trees can be used to keep heat out of your home or office, through new method of passive cooling that could potentially save 20% in air conditioning bills, researchers at the University of Maryland and University of Colorado Boulder have shown.

The research—the latest from materials science and engineering Associate Professor Liangbing Hu and his team to exploit the natural properties of wood for surprising and practical purposes—was published today in Science. Previously, Hu and collaborators have processed wood to be stronger than steel, turned it translucent for an energy-saving window material and demonstrated how it could be used for low-cost desalination.

The current research takes advantage of cellulose nanofibers and the natural vascular chambers inside a living tree, specially processed in a way that creates optical properties in the material to radiate heat away.

The current research takes advantage of cellulose nanofibers and the natural vascular chambers inside a living tree, specially processed in a way that creates optical properties in the material to radiate heat away.

“This is another major advancement in wood nanotechnologies that the Hu group at the University of Maryland achieved: cooling wood that is made of solely wood—that is, no other component such as polymers—can cool your house as a green building material,” said Hu, one of the paper’s co-authors.

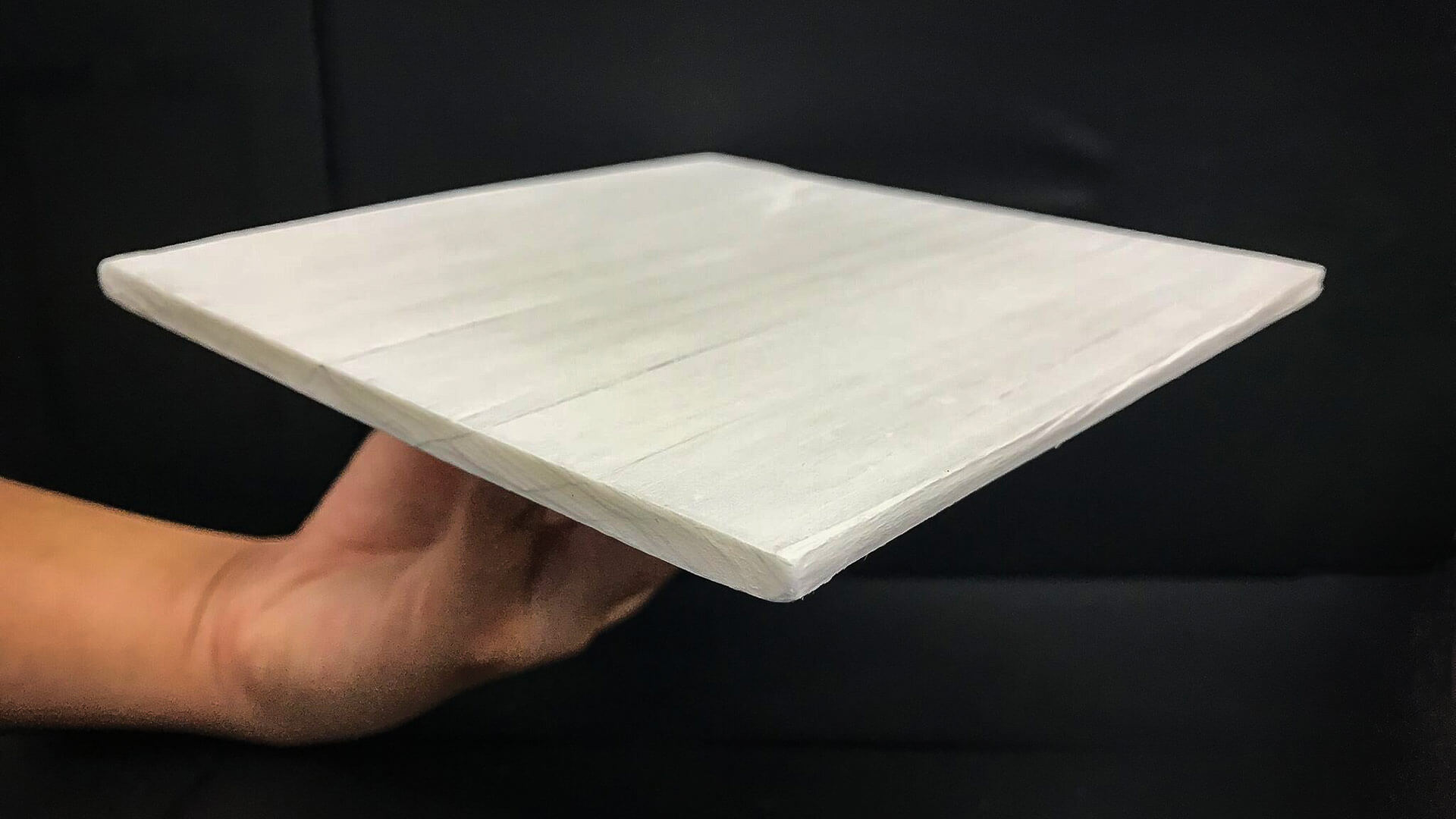

Removing the lignin, the part of the wood that gives it strength and adds color, resulted in a pale material made of cellulose nanofibers. The researchers then compressed the wood to restore its strength and added a super-hydrophobic compound to protect it. The result: a bright white building material stronger than steel that could be used to build roofs that remove heat from inside buildings without any electricity.

Testing on a hot, sunny Arizona farm showed that the cooling wood stayed an average of 5 to 6 degrees Fahrenheit cooler than the ambient air temperature, even during the hottest part of the day. And it stayed 12 degrees cooler than natural wood, which heats up far more easily in sunlight. The team estimated that in buildings constructed since 2004, the invention would save 20% in air conditioning costs.

Wood is ubiquitous as a building material and can be sustainably produced, making it doubly environmentally friendly, when combined with the energy savings from using the material.

“It is a sustainable material for sustainable energy to combat global warming,” said Tian Li, UMD a postdoctoral researcher and one of the paper’s co-first authors.

The other co-first author from the A. James Clark School of Engineering was Shuaiming He. The team at the University of Colorado Boulder was led by Professor Xiaobo Yin and included co-first author Yao Zhai, both of whom work on materials for radiative cooling, including thin films and paints.

Other collaborators include mechanical engineering Professor Jelena Srebric’s team at the University of Maryland; Ronggui Yang’s team at the University of Colorado, Boulder; and Ashlie Martini’s team at the University of California Merced.

Researchers worldwide are impressed by the development reported today.

“This work has greatly extended the use of wood toward high-performance, energy-efficient applications and provided a sustainable route to combat the energy crisis,” said Northeast Forestry University Professor Jian Li, a member of Chinese Academy of Engineering, who is not associated with the research.